Hey, I'm ORBI!

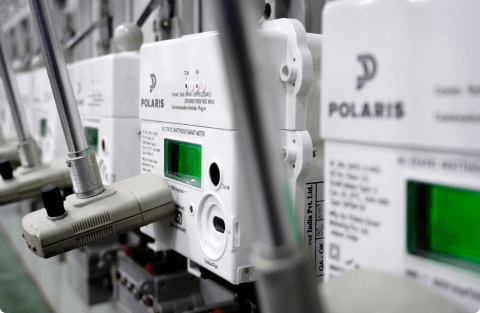

From city grids to smart buildings, Polaris delivers intelligent energy infrastructure that adapts

to your environment. Backed by AI, built in India, and trusted nationwide—our solutions simplify

operations, reduce losses, and support sustainable growth across industries. Our end-to-end smart

metering ecosystem helps organisations unlock efficiency, transparency, and maximise profitability.

SMART Future. SMART World.

Polaris is reshaping how utilities operate—delivering AI-backed prepaid metering systems that are built to scale, optimise, and last.

Featuring wireless connectivity and fortress-grade data security - our solutions reduce manual intervention, prevent power theft, and equip utilities to lead the next energy transition—seamlessly and securely.

SMART Utilities. SMART Governance.

Polaris ensures precise tracking, secure communication, and automated control for both residential, commercial and industrial customers.

Our technology is built to handle the demands of modern gas networks - track consumption and automate billing, making energy management efficient.

SMART Meters. SMART

Distribution.

Built to tackle the complexities of dynamic & fast-moving rental environments, Polaris Smart Prepaid systems bring peace to both landlords and tenants.

Benefits like tariff control, real-time power utilisation insights, energy theft detection and pay-before-use systems, make co-living transparent, efficient & seamless.

SMART Solutions. SMART Living.

With an aim of optimising power consumption, Polaris' intelligent metering systems track

usage across equipment, automate alerts, and reduce energy waste.

Powered by intelligent, data-driven software, and time-of-day tariffs, our system analyses

each appliance’s power rating and daily usage patterns. This allows commercial spaces to

manage power smartly, cut costs with real-time alerts and daily reports.

SMART Meters. SMART Monitoring.

With our 100% Make-in-India hardware & software solutions, Polaris advances a total control over

power management to real-estate providers.

Our plug-and-play solutions can be integrated seamlessly with existing Building Management

Systems. Features like multi-source billing and completely wireless metering simplify

operations, eliminate billing disputes, and enable data-driven efficiency.

SMART Systems. SMART Spaces.

Polaris is transforming industrial profitability with AI-powered, technically advanced

energy solutions.

Built for energy-intensive industries, our intelligent metering systems, integrated with AI

& ML, enable seamless tracking of real-time energy usage across machines and processes.

Through a single app - prevent overloads, optimise consumption, and reduce power-related

costs.

SMART Solutions. SMART

Business.